Which is better: Particleboard or MDF

The answer is to determine exactly which material is better, very hard. It is necessary to consider the purpose, as well as the operating conditions. In terms of the manufacturing process, MDF is much better. This is due to the fact that chipboard (wood chipboard) is made on the basis of fine chips, it requires a large amount of adhesive composition. As a rule, it contains formaldehydes, which can evaporate during use and cause harm to humans. MDF is made on the basis of wood flour, to connect all the elements do not require the use of a large amount of glue. Moreover, it is completely environmentally friendly, safe to use. According to the technical characteristics of MDF and particleboard is also different. The following performance indicators can be noted:

- Strength level. MDF is several times stronger than chipboard. That is why it is used for the manufacture of furniture facades, which are subjected to mechanical stress;

- Resistance to moisture. Two materials have approximately the same level of protection against moisture. But for them a lamination coating can be used, it additionally protects the product from moisture penetration;

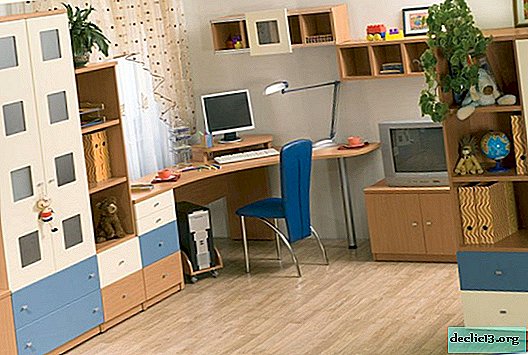

- Scope of application. MDF is more versatile than chipboard. It can be used not only in the furniture industry, but also for the manufacture of various flooring substrates;

- The two materials presented must be protected from elevated temperature, as the products may deteriorate or even catch fire.

To say which material is better (particleboard or MDF) is very difficult, since you need to take into account the features of the application. But according to the technical characteristics of MDF, it is more practical and reliable.