DIY making a double bed, the main stages of the process

Increasingly, owners of country houses are trying to decorate the interiors of bedrooms with wooden furniture made by themselves. Self-made furniture allows you to show the personal talent of the designer, show others your own sense of style, save on expensive interior items. If you want to surround yourself with stylish and high-quality furniture, then a do-it-yourself double bed is suitable for this, which is easy to do, listening to our advice.

Drawing Creation and Detailing

The bed plays a huge role in the life of every person, so it is worth approaching her choice with all responsibility. A comfortable sleeping bed will guarantee a healthy sleep, reliable support for the spine, and well-being. That is why this piece of furniture can be found in every home.

Today, manufacturers offer a lot of different sizes, shapes, and materials for making beds, sometimes you don’t even immediately understand which one is relevant, since the choice is too huge. Therefore, to begin with, let's try to understand the standard sizes of beds for sleeping and relaxing. In size they can be:

- single bed made of solid wood do it yourself (width 80-120 cm, length 190-220 cm). This model is optimal for one person;

- one and a half bed do it yourself from wood to the bedroom (width 120-160 cm, length 190-220 cm). Suitable for one person who likes to sleep freely, or for relaxing the baby with his mother;

- double bed made of wood with a mattress (width 160-230 cm, length 200-220 cm). Models are intended for couples, such designs are comfortable, practical.

It was decided to make a double bed with a back on its own? The main details in the work will be:

- classic bed made of timber;

- drawings that help in the preparation, manufacture of structural elements of the product;

- an action plan with the division of operations into stages.

To start work on creating a bed is to create a drawing, which carefully describes all the details with an exact indication of their size. It is also required for calculating the actual amount of materials and accessories, as well as their cost. Errors at this stage of work can lead to disastrous consequences. In the best case, you will have to spend more time on additional operations, in the worst - you will have to purchase new material in return for damaged parts.

If there is little experience in these matters, you can use ready-made diagrams and drawings. For an experienced craftsman, creating a bed for two people of a non-standard shape is not difficult. For beginners in this matter, we recommend that you choose a simple rectangular shape.

Preparation of tools and necessary parts

In the process, you will need to purchase the following items from the nearest building materials store.

| Material | Sizes, cm | Quantity, pcs | Wood species | To create which part is used |

| boards | 2,5×20×240 | 4 | Pine | frames |

| boards | 5 × 10x240 | 3 | Pine | support beams |

| boards | 2,5×5×240 | 3 | Pine | decorative finishes |

| bar | 10×10×240 | 1 | pine / fir | legs |

| boards | 2,5×7,5×240 | 19 | Pine | rack bottom |

Headboard Materials

Headboard MaterialsThe volume of materials is calculated based on the drawing of the future product, indicating the dimensions of each of the necessary elements. It is better to purchase a little more natural wood, so that it is definitely enough for the manufacture of the entire structure.

Specialists in the manufacture of furniture for residential premises recommend choosing a high-quality tree without knots in the manufacture of a double bed frame. The presence of a large number of knots will require a lot of time for grinding. And you can save money on the purchase of material for supports and lamellas of the lattice. The material for the supports can be of the second grade, it costs a little cheaper. And for lamellas, choose the cheapest options.

If you decide to make a bed with a lifting mechanism made of metal, then you will need to buy more materials, because in addition to the main frame, you should also make a lifting frame for the sleeping bed. Be sure to include both the type of building material and the type of lifting mechanism in the drawing.

As for the relevant tools for the work, you will need:

- measuring tape for measuring space, structural details;

- circular;

- special Kreg Jig kit, allowing you to drill holes at an angle;

- electric drill for organizing holes;

- adhesive for bonding wood surfaces;

- square with the ability to adjust;

- self-tapping screws (30.50.60 mm);

- water-based acrylic varnish;

- wood stain, allowing to emphasize the natural beauty of the tree, improve its performance;

- brushes for painting wooden surfaces;

- sandpaper or grinder for grinding parts of a future design;

- putty for wood surfaces.

The process of sawing parts for the bed must be performed strictly following the dimensions of the drawing. Next, we will describe in stages how to make a double bed with your own hands.

Instruments

InstrumentsAssembly process elements

Many people wonder how to make a double bed with their own hands, where to start? The assembly of the future design can be conditionally divided into stages, which will allow a more detailed description of each operation.

Frame

They begin the process of making a double bed with their own hands from wood from the main frame. It must certainly be durable, have high strength characteristics in order to serve the owners for a long time.

Using a drill, drill holes for fasteners with a diameter of 30 mm in the prepared parts. Clean the ends of the boards with sandpaper, and preferably with a grinder, so that there are no chipping marks on the surfaces. Open in two layers with adhesive for wooden surfaces, allowing each of them to dry thoroughly. At the end of the drying process, insert the acquired screws into the drilled holes, fastening the boards using a screwdriver or a screwdriver.

If excess adhesive appears at the junction of the boards, they must be removed with a damp cloth. At the end of the work, check the straightness of the corners of the product with a construction square. When the frame dries, paint it with a stain. Modern models of double beds can be equipped with a solid or slatted bottom. The first option is made from a single sheet of plywood. To create slats for a double bed, plywood is cut into blocks of the same width.

All boards must be sanded beforehand.

All boards must be sanded beforehand. Boards fastened with self-tapping screws

Boards fastened with self-tapping screws Ready frame

Ready frameBack shield

The headboard should be made for several reasons:

- this decorative element enhances the beauty of the whole structure, allows you to create a cozy atmosphere in the room, gives the interior completeness, concise look;

- it acts as a reliable protection for walls from dirtying, rubbing;

- leaning on the head is always nice.

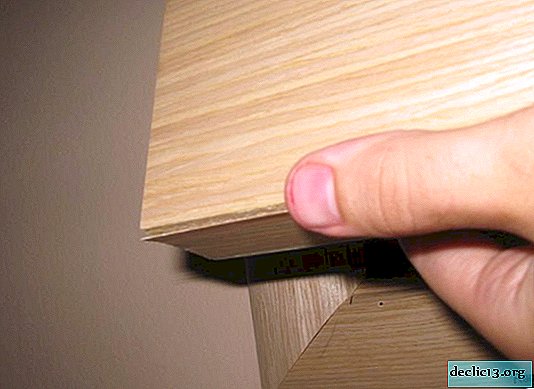

Often a wooden double bed has an impressive weight, so the headboard should be made removable. If in the future the structure needs to be moved to another place, the back can be easily dismantled. For the backrest, use a furniture board made of two boards 6 m long. They are cut into pieces, which are spliced into the shield using dowels, glue. In order to completely match the dowel holes, place marks on the edge of the board and punch small nails without a hat with the help of pliers.

To give the bedroom place a more beautiful appearance, the headboard can be decorated in various ways, coated with foam and sheathed with textiles. If the backrest shield is not planned to be trimmed with upholstery, be sure to sand it carefully so that there are no chipping marks on the surface. It’s nice to touch the polished surface, and poorly processed wood can cause splintering. Next, the surface is treated with a primer, open with varnish or stained with paint to increase the protective properties of wood.

Headboard

Headboard Cut out the head

Cut out the head Backrest mount

Backrest mount

Installation of slats

Next, you need to make lamellas for the bottom of the bed. To make the process go faster, create a reference rail, according to the template of which make the rest of the lamellas. Align the ends of the products, outlining the line along which you want to make a cut. When a sufficient number of lamellas are made, they are well polished. Further, each of them is individually fixed inside the frame of the future product using self-tapping screws.

It is important to understand what level of load will be on the lamellas. The greater the total weight of users of a double bed and the mattress itself, the stronger the slats should be. Make them wide and mount on the frame with a minimum step. If the load on the frame is minimal, then the lamellas can be made narrow and mount them away from each other.

An orthopedic mattress is laid on top of the lamellas, which is selected taking into account the structural features of the body, the age of its owners. Such a product for two people will allow you to get enough sleep during sleep, to restore strength.

Reiki for the base

Reiki for the base Mounting rails

Mounting railsLegs

For the manufacture of supports, use a bar with a cross section of 10x10 cm. From it, you will need to make 6 bars 10.5 cm long, which are carefully sanded. To determine the mounting locations of the central supports, measure half a meter from the ends of the support beam. Draw straight lines in the center, circle the perimeter of the supports, which will allow you to drill holes quickly and without errors. The installation of support legs on the frame is done using a screwdriver and self-tapping screws.

If you don’t have time to make supports on your own or if you want to give the construction some mobility, you can choose wheels for it. Such details will allow you to easily move the bed for two people to another place in the room. You can also pick up metal supports of curved shapes, the original color. This will diversify the design of a standard bed, made independently.

Leg blanks

Leg blanks

Headboard decoration

The external aesthetics of the bed largely depends on the shape of the head. It can be round, square, rectangular, and also have a non-standard shape. For example, to have the shape of a star, a dome. To make a custom back, you will need a piece of paper and an electric jigsaw.

Note that the shape of the back will largely determine the place of its attachment to the structure frame. Non-standard forms are better not to be mounted on a sleeping bed, but hung on a wall. As a result, the headboard and bed will exist separately, but if you move the structure close to the headboard, you get a complete picture.

No less important are the materials from which the head of the bed is made and with which it is decorated. For expensive interiors fit:

- genuine leather, suede - very expensive materials, so they are suitable for creating stylish, luxurious interiors in a bedroom;

- eco leather - excellent performance is demonstrated by this alternative to genuine leather. Eco-leather is inexpensive in cost, practical, beautiful, therefore it is often used in furniture production;

- velor, velvet - beautiful, stylish options, however, over time they can accumulate dust. Therefore, you will have to look after such upholstery a little more often.

The material is upholstered on a wooden frame of the head of the bed, fixing the joints with a construction stapler on a wooden board. If the back has turned out to be an impressive size, you can fix the upholstery material in several places on the front side. So that in the end the head of the bed looks neat, ugly braces are covered with decorative buttons.

The use of rhinestones, Swarovski crystals allow you to decorate the back of a double bed, which you made yourself. From these small decorative elements you can lay out a mosaic, ornament, curved lines and patterns. Still good options for decorating the headboard of a makeshift bed for two are metal forged elements, wood carvings. But it is worth remembering that when decorating a bed for two in a similar way, its cost rises at times. But the finished product will be unique and inimitable.