Varieties of varnish for furniture, their main areas of application

Lacquered home furnishings look elegant and expensive. They are resistant to chips, scratches, cracks, damage by insects and rot. Furniture lacquer is made on a different basis: water, acrylic, oil, resin with organic additives. Each variety has its advantages and disadvantages, features of application. Coatings are offered with a matte or glossy finish, which affects the appearance of the finished product.

Appointment

Furnishings made of wood, particle boards are actively used in home and office interiors. Under the influence of external negative factors, products may become deformed, crack, or become moldy. To protect and prevent the loss of an attractive appearance, special varnishes for furniture are used. Tools have a film-forming property, which manifests itself after applying the composition to the surface of the furniture and its complete drying. The finished product is varnished at the final stage of processing.

Furniture varnishes can have various shades, a matte or glossy finish, but their coating remains transparent or translucent. This allows not to hide, but, on the contrary, emphasize the natural beauty of the wood structure.

Depending on the degree of gloss of the coating, the following types of product are distinguished:

- Matte varnish for furniture is practical, there are no fingerprints or stains on it at all. Frosted surfaces are appropriate in business, office premises, they are combined with chrome fittings;

- Glossy coatings have a maximum degree of reflection of light. Glossy furnishings often become the main accents of the interior. They look noble and elegant;

- Semi-gloss and semi-gloss varnishes are universal. They are suitable for decorating any furniture, have a moderate sheen and handprints are not very visible on them;

- Some products are suitable for garden furniture, they are resistant to moisture, contain substances that protect against the negative effects of UV rays.

Matt

Matt Glossy

Glossy Semi gloss

Semi glossVarieties

There are several varieties of varnishes that differ in composition, appearance of the coating and the degree of environmental friendliness. To evaluate which product is best in each case, you need to familiarize yourself with all kinds.

Oil

Means are obtained by mixing linseed oil with turpentine and a hardened resin. Today, to reduce the cost of the product, natural components are replaced with synthetic ones. The solvent component is White Spirit.

The product hardens after evaporation of the solvent, forming a very durable coating. For garden furniture oil varnishes of high fat content are suitable, which have strength, water resistance, elasticity. Furniture for the interior can be covered with products with a low oil content and a high percentage of resins. Such formulations dry out quickly. A surface coated with low-fat varnish can be sanded to a glossy finish.

The oil product is sold ready-made, does not require mixing. If it is necessary to add matting or tinting components, they are thoroughly dissolved in varnish. The tool has a universal purpose, care for lacquered furniture is minimal.

Nitrocellulose

The product is obtained from a mixture of organic components, resin and colloxylin. Nitrocellulose does not dissolve in water, a special component is used for this. This varnish is suitable for processing any furniture made of wood, including products for home and outdoor use.

After coating, it dries completely in 60 minutes at a temperature of about 20 C. The resulting film has high hardness and smoothness. The product can be characterized as odorless, quick-drying. It is very popular in industrial and home use.

Water-based products

Waterborne furniture lacquer is popular due to its high environmental friendliness. The product does not contain toxins, does not smell. When applied to the furniture surface, the varnish dries quickly, the film is durable and highly elastic. It is suitable for decorating furniture for any purpose, including the nursery. The water base of the product provides its high fire safety.

Water products are divided into several types:

- One-component

- Two-component,

- Acrylic

Two-component products with the addition of polyurethane are stronger than those made on the basis of a single component.

A relative disadvantage that water-based varnish has is its low moisture resistance. Therefore, they do not cover garden furniture and bathroom furniture.

Acrylic

The product is obtained by dissolving acrylic resin in water. The composition also includes several varieties of solvents, called coagulating agents. They turn the resin into a strong film after the evaporation of water. In the jar, the acrylic furniture lacquer has a milky white color, but when dried it forms a transparent, colorless coating.

Use the product only in conditions of high temperature and low humidity. Dampness, low temperature can lead to the fact that the varnish does not dry out, the film does not harden. The tool is quick-drying, so the painted product can be used in a day. The surface of wood with such a coating does not turn yellow over time, retains its natural texture. You can use such varnishes in nurseries, healthcare facilities and the social sphere.

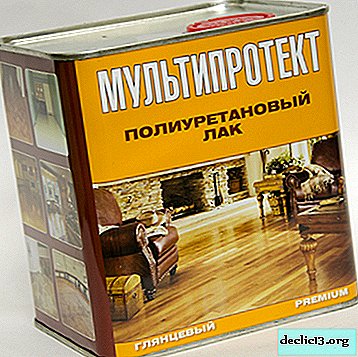

Polyurethane

The composition of the products includes polyesters and diisocyanates, they are divided into one-and two-component. Mixed products require the combination of components before starting work. Polyurethane varnishes have increased coating strength, elasticity.

The treated surface of the furniture will not be subject to abrasion, it is resistant to mechanical damage. Transparent coating does not darken for many years, it applies to all types of furniture. Polyurethane varnish is superior in wear resistance even to compositions with a high oil content.

Alkyd

Products are based on synthetic alkyd resins. Varnishes are easy to apply on any surface, including natural wood. The coating is moisture resistant, withstands intense humidity and temperature extremes.

You can cover with such varnish not only cabinets, beds, but also garden sets, built-in furniture of open or closed verandas. Alkyd compounds are superior in many respects to oil, acrylic.

Craquelure

A special kind of furniture varnish is craquelure varnish. The product is used to obtain the effect of aging. Achieving this effect is possible due to the difference in the drying time of the product itself and the finish coating that is applied to it. The varnish composition dehydrates the paint with which the product has been treated, causing cracking on the surface.

Only a dry surface can be varnished. A layer of paint is applied to the slightly dried varnish layer. To achieve a fine-textured pattern, the varnish layer needs to be dried longer. It is recommended to apply such a coating on products that are intended for placement in the antique style, vintage. For the restoration of antique products, shellacs are used on a natural basis.

Selection rules for different materials

Lacquer products can not only give the furniture an attractive appearance, but also extend their life. However, it is important to choose the right product. Before choosing a jar, it is recommended to evaluate the following aspects:

- For home use, do not purchase professional products. A beginner will not succeed in achieving factory application;

- Assess the degree of deterioration of the furniture structure. For coloring products or their parts, which have the maximum load, choose two-component polyurethane compositions. This is true for tables, chairs. When decorating casement closets, frames, platbands, you can use a nitrocellulose product or varnish for furniture based on water;

- Depending on the purpose of the piece of furniture and the conditions in which it will be used, choose the most resistant compounds or products based on water. For the furnishings of living rooms, oil, acrylic and alkyd products are most suitable. With repeated cleaning, they prevent cracking. Outdoor furniture items are covered with products with antibacterial additives, eliminating the appearance of rot and mold.

When choosing, it is important to consider how much time you will need to use the item. If you have only 4-6 hours, then use a water-based product. Processing with an industrial hairdryer helps speed up the drying process.

If you plan to varnish products from wood boards, models with curly cuts, panels, then it is possible to use varnish in aerosols. It does not require mixing and brushes for coloring. A wide palette of shades allows you to choose both the darkest and white product.

Means equally equally to lie on smooth and carved surfaces, does not leave unpainted areas or stains. Lacquered furniture gains shine, looks elegant and is easily cleaned of impurities. It is also worth paying attention to the manufacturer and the cost of the product. The cheapest products will not create a durable, durable coating. The maximum cost are funds that are suitable for outdoor use. Products for internal use, such as oil, dry for a long time, but form a film that is resistant to abrasion.

At the request of the consumer choose a transparent or tinted varnish. Colorless products are suitable for products from an expensive massif that has a beautiful natural texture: beech, oak, mahogany. It provides the necessary protection, but does not hide the natural beauty. For products from inexpensive species: pine, walnut, birch, you can apply color compositions. They will give the furniture a more stylish appearance, make the interior richer. The proposed color palette includes a wide variety of shades of wood, as well as white and black colors, other colors of the RAL palette. Depending on the degree of penetration into the wood, choose a product a shade darker or lighter than desired.

The most natural appearance of the finished product allows you to get a matte product. He does not emphasize the existing flaws, but requires careful grinding of the surface. Glossy coatings are relevant for furniture in dark colors. They emphasize the structure of wood fibers, but require the smoothest surface of the workpiece. When choosing a glossy composition, it is more difficult to take care of polished furniture, fingerprints are visible on it.

Parameters and specifications

The main differences between different types of furniture varnishes can be estimated by their technical characteristics. Here is a product comparison chart:

| Product Group Name | Dry residue,% | Viscosity | Consumption, g / m2 | Resistance to damage | Cost | What material is applied |

| Nitrocellulose | 5-27 | 38-50 | 30-150 | Weak | Low | Wood veneer |

| Acrylic | 20-45 | 30-80 | 110-150 | Moderate | Average | Wood, veneer, MDF |

| Polyurethane | 25-70 | 40-75 | 80-150 | Strong | High | Wood, veneer, MDF |

| Water based | 25-35 | 30-70 | 80-120 | Moderate | Average | Wood veneer |

Furniture varnishes used for decorating and giving finished products an attractive appearance, contribute to an increase in their service life. Depending on the main active ingredient, acrylic, aqueous, alkyd, polyurethane, oil products are isolated. You need to choose the most suitable product based on the requirements for durability and environmental friendliness of the coating.